St. Louis Galleria To Improve Pedestrian Access, Adding ADA Access Routes From Public Transit Stops

I’m very pleased to announce The Galleria Saint Louis & General Growth Properties, Inc. (GGP) will make substantial site modifications to better accommodate pedestrian visitors to the mall.

Thankfully GGP was very cooperative from day one, they willingly recognized the access issues I raised and quickly agreed to address them. For the last 18+ months we’ve been working together on a mutually agreeable resolution. GGP and I share a desire to increase accessibility for persons with disabilities.

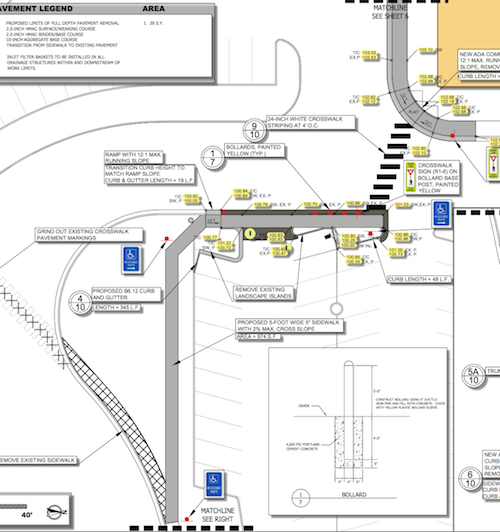

For those pedestrians arriving at The Galleria via the Richmond Heights MetroLink light rail station, a new pedestrian access route will be completed.

Additional pedestrian access routes will be constructed as well.

Again, I’m very pleased to be able to make this announcement.

— Steve Patterson

Follow the path of least resistance. Beauty and curvy lines are great, look great. But pedestrians, especially with packages, prefer direct pathways. One would think this would have been done years ago.

Years ago there wasn’t a Metrolink station that generates a lot of pedestrian traffic.

What was the purpose of building the sidewalks on Galleria Pkwy in the first place?

The Blue Line has been in operation since 2006. Seven years is a long time.

You’re right. This appears to be a great improvement that will benefit all pedestrians. The direct route with 90/45 degree directional changes is typically the most user friendly and cost effective. Curves and circles cost money to build in the industry. But next time you see an ADA compliant pathway that follows a circuitous pattern, don’t necessarily blame it on a landscape architect with whimsical or capricious design tendencies. Sometimes (even often) a stodgy old civil engineer might have had a hand in its design, because a curvy pathway is most cost-effective in negotiating grade changes that otherwise would require major soil import or export, water run-off considerations and even retaining walls, intermediate landings with handrails, etc. A meandering path is better than no path, especially when the budget is a tight.

It’s about time. The Galleria should have realized how embarrassing it was, years ago, that there is not a single continuous sidewalk from Brentwood to the mall. Even for able bodied pedestrians, the walk is confusing and unpleasant. That the sidewalks will now be ADA accessible is just icing on the cake.

Most malls are/were not designed to offer good pedestrian access from their perimeter simply because most are bordered by major thoroughfares that have little pedestrian activity to start with. Most malls are self-contained entities set in a sea of surface parking, not in larger urban neighborhoods. And even where sidewalks are provided, most shoppers will walk through the parking lot because it provides the straightest line between their vehicle and the door they’re using to access the retail wonderland. The ADA mandates that accessible parking be placed as close to the door, as well, so that disabled shoppers are protected from most other traffic. None of this encourages pedestrian activity outside the mall property, and that was the case here until 2006, when the Metrolink station opened, and about the same time the Boulevard was completed – there was little on the east side of Brentwood to attract pedestrians, so any sidewalk was more decorative than functional.

This is most certainly an improvement. Although, I believe we need to get away from annotating 2% max slope/cross-slope on our drawings. That figure is a code maximum to ensure drainage, but is excessive. 1.5% is adequate cross-slope and if the sidewalk already slopes more than 2% in the direction of travel the water already is draining off of it. Parking spaces and access aisles are not to have a slope in any direction of more than 2%. The drawings only indicate a 2% max slope in one direction. It is essential the final product is surveyed to ensure the sidewalks, ramps, access aisle and parking spaces are truly compliant.

Agree and disagree, mostly disagree. 1.5% cross slopes on surfaces with 1 to 2% slopes in direction of travel is inadequate in geographic areas subject to especially heavy, sustained rainfall: the Gulf Shores area of Alabama where frequent and heavy rains are the norm , even Southwestern California (Venice, Santa Monica, Malibu) where it does’t rain often, but when it does, maximum allowable slopes leave pedestrians’ feet less wet (certainly not dry!). I’ve seen similar gully washers here in STL. I like to indicate greater tolerances in all my details, then design accordingly, because the work is done in the field vs in a laboratory where all conditions are perfect.

When the code dictates a 2% maximum, it suggests that anything less than the maximum value is acceptable (or they would have said it must be 2%). However, contractors see 2% maximum and rarely consider building it with less slope. Unfortunately, I’ve seen far too many sidewalk projects that call out for 2% max that end up exceeding 2%. And I’ve seen contractors rip out blocks of sidewalk (at their own cost) to correct their mistake. However, contractors often get away with non-compliant construction and we are all left with dealing with its effect (typically not just less wet feet). We did a little field test and found that when walkways are at 2% or greater, people using wheelchairs tend to roll in the direction of the slope. They therefore have to over-correct with one arm, placing greater strain on that one arm often causing shoulder problems. Certainly the code maximums and minimums are in place for a reason, but if you’ve ever sat in on the conversations that surround the development of the codes, you’d may be surprised at the research and sometimes politics required to overcome outdated codes.

In many cases involving remodel or infill work, the cross slope is actually determined by existing fixed points that must be met. So I wouldn’t find myself taking the maximum off the table just because historically some contractors have ignored it. When greater than 2% is required in order to meet existing fixed points, I haven’t done my job as the engineer and need to go back to the drawing board, which I have done in the past. When two parallel screeds are set up to form sidewalk bulkheads, and there’s a 2% or less difference in elevation between the empty screeds, even the slightest crowning in the wet concrete can result in a slope that exceeds 2%, even minimally. I’d like to think that we can attribute that out-of-tolerance to the human condition and understand that the trades are often fighting inclement weather conditions and other non-laboratory environmental factors, just to get the work completed on schedule..

Human condition, fighting weather, and other non-laboratory environmental factors, just to get the work completed on schedule…..so you mean cutting corners.

But just the other day : “In the last several years, I’ve found that the construction workforce is more intelligent and more committed to ethical performance in their professions than ever before ”

Or

“The construction industry, comprised of human beings subject to the known frailties of humanity, has done a 180 over the past 10 years. In the St. Louis area, for example, where you’ll find some of the finest union workmanship in the country, no longer is the superintendent some rough-cut carpenter wearing bibbed overalls and mud-covered buckle galoshes, with cigarette hanging from both sides of his mouth. He’s an intelligent, articulate, experienced carpenter or laborer with business savy and generally with enough experience under his belt that he knows where he needs to keep his attention focused, and he recognizes good workmanship and takes decisive action when he doesn’t see it happening.”

So much for keeping focused and committed to their professions.

Like Pavlov’s mouse, you didn’t disappoint. Why did I know my last post would bunch up your panties? I just got off an airplane, and I am answering this in the taxi. Forgive any auto-mis-corrects. Let me explain in terms that I’m certain you will understand. Let’s say you are cutting and styling your neighbor’s hair on a humid afternoon and when you’ve finished you noticed that it just doesn’t “poof” like it did last time. Did you cut corners? Let’s say your last creme brulee stuck to the sides of the ramekin, but you followed the recipe to the T. Did you cut corners? Or maybe the pastry puffs you recently made sorta deflated as you removed them from the oven. Did you cut corners? In my opinion, no. But I defer to your final judgement since I’ve gleaned that this your area of expertise.

First of all, when specs are written with a stated minimum and maximum %, there is also a tolerance percentage, (in addition to that maximum and minimum)that is allowed by ASTM (a standards/governing force in the industry). So if the concrete elevation adjacent to my right screed is slightly over the maximum 2% specified, the concrete can still be argued (successfully) be meet the spec. And no Saturday morning superintendent can or should do anything about it.

Most materials have an implied or inherent tolerance factor. Concrete, which consists of sand, aggregate, cement, and air is mixed in volume in a dusty gravelyard, distributed via truck in temperatures ranging from 28 deg. F to 100 deg F +, is placed using either wheelbarrow, crane bucket or pump, and is placed in sunlight conditions that range from overcast to sunny…to hot, humid/dry and unbearable! The aggregate may or may not have been rained on last night, and the sand might be moist or dry. Much depends on where it all is positioned in the pile…..and how much of the pile was used before your load was batched. When a pour will require 30 9-yd trucksfull, within a period of 3 hours +/-, you won’t find yourself sorting through the pile of sand or gravel with a teaspoon and a meatfork culling out the oversaturated sand or gravel-dry aggregates! Nonetheless, all these ingredients which are not controlled (or controllable) like the flour or cornmeal that you use from your kitchen cabinet, are used in a designed concrete mix, called a “mix design”. Essentially the mix ingredients support a very important water-cement ratio. That’s its most important job! If you get the water-cement ratio right, many of your cracking problems will go away. But let’s say the design mix is a good one but the weather is really hot…..and dry. Premature evaporation may make maintenance of the water-cement ratio impossible! In that condition, a superplasticer additive is used in lieu of some of the water, which gives the concrete a workability that otherwise it wouldn’t have achieved. This will help to prevent blowups. The “call” to use primarily water vs. a plasticiser, or vice versa) is a call made by the finisher foreman or his representative, not by the engineer, owner or Saturday sidewalk superintendent. Depending on the call, it’s possible that the finish product will be affected–not necessarily adversely, but just different. Plasticiser can affect the air entrainment in a batch of concrete, and air entrainment can impact final elevation. So on days when plasticiser is absolutely needed and when the volume of air entrainment is increased, it’s possible that by the time the placed concrete has set up adjacent to the screed, some of the “air” has already left the mix, resulting in the ” minus” situation that I referenced above. Is this cutting corners? I’ll answer that question: NO! …..as long as it meets the minimum/maximums….PLUS the ASTM tolerances.

I joke about construction management….largely because most of the CM firms in STL employ under-experienced personnel to “supervise” the construction. They may be degreed engineers or degreed architects, or they may have degrees in “construction management” (??????), but they don’t necessarily have real-life experience in the industry….just as you and some others in this blog whose comments suggest that you expect absolute perfection. The industry is not perfect. But is it better than it was when my father was active in the industry? At least in STL, there are trade unions which help to control the workmanship. Where I grew up in Elberta, AL, there were (are) no unions and the workmanship suffers accordingly.

I hope this speaks to your snarky comment. My cab ride is almost over, and I’ve arrived at my intended destination where tomorrow the contractor will pour 286 CY of 6000#, 6% air entrainment concrete with plasticiser, with an entrainment spec of + 1%, -1-1/2%. Now you should know enough about concrete to say for certain what kind of a weather day we are expecting tomorrow in Kansas City. If things change, we’ll likely use a mix design that utilizes more water than plasticiser. Got it?

Still no excuse or explanation of either cutting corners in one post or or all are professionals in the next. Statements you made, not myself or other posters.

Now excuse me, Pavlov’s dog needs feeding.

I remember my grade school teachers, especially Ms. Harmon, who encouraged us to read everything in print so that we’d improve our reading skills, including reading comprehension. It’s a shame that you didn’t meet Ms. Harmon along the way. You should offer your neighbor a free hair styling session when the humidity drops.

You have a fixation with people’s hair. Weird.

Existing condition are considered by the code and allowance made within reason as long as modifications are made accessible to the greatest extent possible. I certainly don’t advocate allowing contractors to use inclimate weather or the necessity of meeting a schedule as an excuse to provide products that are not at least compliant with the existing codes. Unfortunately once a product is built out of compliance the cost to correct it because a financial burden and the barrier (newly constructed) remains until someone is willing to force the issue.

This is definitely a step in the right direction! Have you seen there are also new sidewalks poured just in the past month at Brentwood Pointe (the Dierbergs plaza) and alongside Hanley Industrial Drive heading southwest from the Brentwood-I-64 MetroLink station? I wish it was a more direct path to the platform, but at least it appears to my untrained eye to be compliant with ADA standards.

Also, many people may not realize there is already a (somewhat circuitous) pathway leading from the Maplewood-Manchester MetroLink via driveways and parking lots to the Lowe’s and Wal-Mart plaza (Maplewood Commons). It’s probably not ADA-compliant, but it certainly is shorter than walking all the way out to Hanley and then back into the center.